WELCOME

With dynamic growth in water and wastewater management, enflow has created a new state of the art engineering department that is active in the field of wastewater treatment. We design sustainable systems, focusing on water recovery and reuse, and offer integrated solutions for the treatment of municipal and industrial wastewater.

ENFLOW ENGINEERING

TREATMENT TECHNOLOGY

Enflow having experience with all tested types of treatment, offers biological wastewater treatment systems that

apply the MBR (Membrane Bio Reactor) method.

Membrane Technology

Membrane Bio-Reactor (MBR) systems are a combination of the classical and widely used activated sludge method and ultrafiltration using membranes. The innovative feature of this method lies in the use of special membranes featuring novel technology, which are immersed in the mixed liquid (biomass – treated). The philosophy of MBR systems is based on the use of a bioreactor and membrane filtration as a single system for wastewater treatment instead of the classical system of bioreactor and final settling tank. The treated material passes through the membranes and is removed while the biomass is retained and remains in the treatment system. Thus, the final settling tanks of the activated sludge system are replaced by membrane filtration units (MF or UF type). The high concentration of biomass in the bioreactor results in achieving complete decomposition of organic matter (small quantity of excess sludge) and nitrification within a very few hours.

MBR TECHNOLOGY

BENEFITS

Today, there are several MBR systems used in a variety of applications, which are gaining ground and are even tending to replace conventional wastewater treatment methods due to the advantages of MBR technology.

Enhanced Membrane Technology

Simultaneous disinfection of the effluent produced with lower chemical consumption

Water of superior Quality

Compared to the classic treatment systems, the MBR technology can achieve high effluent quality

Reduced space requirements

Reduced footprint requirements due to the lower volume required for bioreactors.

Low sludge production

Less excess sludge to be removed due to increased residence times and low organic loading rates.

OUR PACKAGE SOLUTION

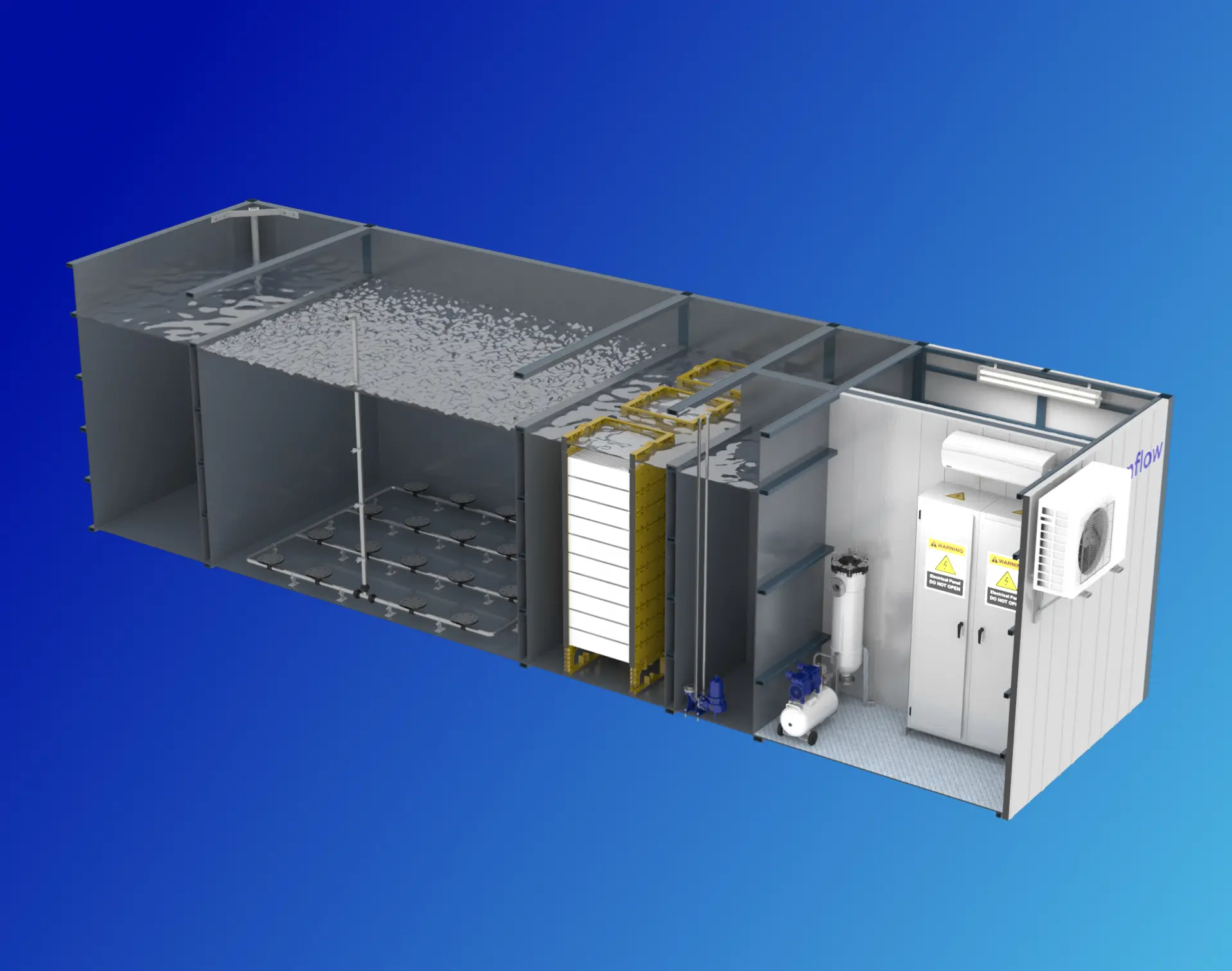

Discover the MBR Packaged Plant by Enflow Engineering

Enflow engineering designs and offers packaged systems utilizing MBR technology for the treatment of municipal and industrial wastewater. These systems represent a comprehensive solution, ready for installation with pre-installed electromechanical parts and membranes inside a container.

The systems are self-contained and fully automated, and are mounted on a concrete slab, significantly reducing the cost of installation and field construction work.

Applications

- Municipalities

- Industries

- Hotels & Resorts

- Hospitals & healthcare centres

- Military units

- Campings/ Summer camps

- Schools

- Office buildings

- Accomodation centers

- Reception centers

COMPACT WASTEWATER TREATMENT

Key Features

Our MBR packacked plants have the following benefits:

Easy to transport

Easy to transport, by its container structure

Quick assembly

With all equipment inside the container and easy commissioning thanks to the pre-assembled

installation.

Fully automated

PLC-based electrical control system for ease of operation, reduced maintenance requirements and remote monitoring.

Low operation and maintenance costs

Reliable technologies and easy operation, requiring no supervision (no need

for operator presence) with the exception of regular performance and maintenance checks of equipment and

membranes.

Scalable

The systems allow new units to be added to create the appropriate model with the necessary capacity

Portable

Ability to relocate the installation, thus adding greater flexibility to the investment

Shorter completion times

Due to reduced on-site construction work, project completion times are shorter

Less space requirements

The units require less installation space due to the compact design and high biomass

concentration.

HOW IT WORKS

4 steps in wastewater treatment

A typical nutrient removal process design consists of four stages:

- The waste is sent to the anoxic tank where biological removal of nitrate is achieved. For stirring the contents in

each anoxic zone, there is an underwater stirrer in a suitable position, accompanied by a lifting system. - In the prolonged aeration stage (aerobic zone), oxygen is supplied through an underwater diffusion system in

order to achieve the biological oxidation of ammonia to nitrate, as well as the degradation of organic matter in the

wastewater. - In the final treatment stage, the MBR membranes separate the treated waste from the activated sludge via

filtration by means of pumps. - The sludge overflows into the deaeration tank to reduce DO levels and is recirculated back to the first stage.

Excess sludge is discharged through automatic valves.

FLOWPAC

MEMBRANE BIOREACTOR (MBR) PACKAGED PLANT

Models

Enflow engineering offers a wide range of package and modular MBR Treatment Plants to meet the needs of any application. This type of compact solution is offered in the following models according to their treatment capacity. Standard models serve daily volumes from 12.5 m3 up to 200 m3.

| MODEL | N-MBR12,5 | N-MBR25 | N-MRB50 | N-MBR100 | N-MBR150 | N-MBR200 |

|---|---|---|---|---|---|---|

| MAX DAILY FLOW (m3/d) | 12,5 | 25 | 50 | 100 | 150 | 200 |

| EQUIVALENT POPULATION (150 l/eq.d) | 50-65 | 120-140 | 240-260 | 480-520 | 720-780 | 950-1000 |

| DIMENSIONS(LXWXH) | 6X2,5X2,5 | 7X2,5X2,5 | 10X2,5X2,5 | 14X2,5X2,5 | 2Χ(10X2,5X2,5) | 2Χ(12X2,5X2,5) |

| MEMBRANE AREA (m2) | 50 | 100 | 200 | 400 | 600 | 800 |

| MATERIAL | St37.2 Epoxy Painting or PE UV resistant | |||||

| DATASHEET | Donwload | Donwload | Donwload | Donwload | Donwload | Donwload |

Customized Solutions

Our engineering department designs and manufactures customized sewage treatment plants upon request, tailored to the specific consumption requirements and characteristics of the wastewater, achieving the required efficiency and quality of the treated effluent.

FLOWPAC

MEMBRANE BIOREACTOR (MBR) PACKAGED PLANT

Flowpac Information

Effluent Characteristics

Flowpac packaged palnts, with MBR Technology ensure maximum performance achieving high effluent quality compared to the conventional systems or to the quality required by regulations for reuse for or other secondary uses.

Parameter

Performance

ENFLOW ENGINEERING

Projects

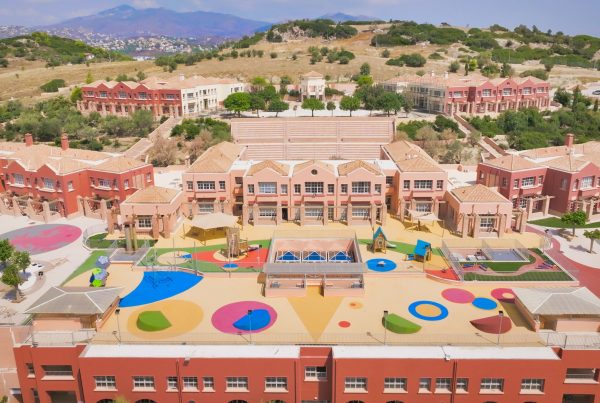

City Plaza

166 74 Glyfada, Attica| Greece

Contact Form

Do you have a question about our products or services?

Get to know enflow's products and certified solutions for water management and treatment

We are always available to offer you our know-how and material!